Tekenwerk bij een chemieconcern

September 2021

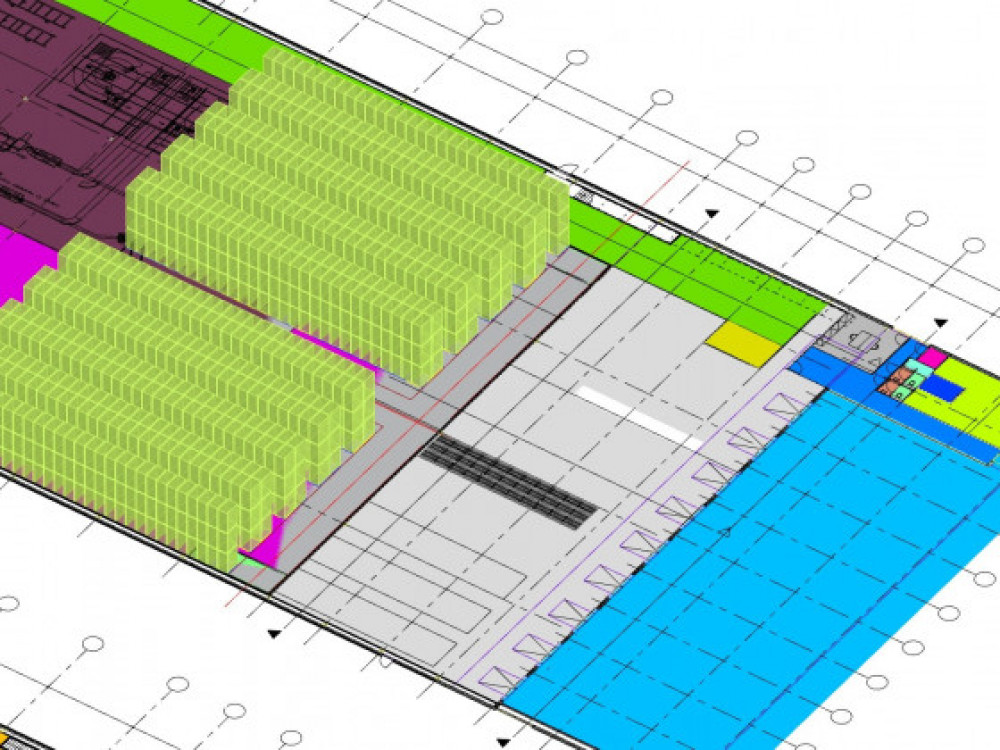

Dapp heeft voor een chemieconcern in de Betuwe gedurende een lange periode geholpen met het verzorgen van het tekenwerk van een van de productie plants. Hierbij ging het vooral om het in het veld nalopen van installaties en het hierbij opstellen van P&ID's (Piping and Instrumentation Diagrams) in het gevraagde pakket AutoCAD Plant 3D (een gespecialiseerde versie van AutoCAD). Doordat de professional van Dapp zelfstandig aan de slag kon en kennis had van zowel P&ID's als het tekenprogramma is dit voor een klant een zeer waardevolle samenwerking gebleken die tot op heden loopt. De samenwerking met de klant heeft geleid tot tekeningen die extra inzicht bij het uitwerken van projecten en helderheid voor de operators geven. Regelmatig worden door Dapp wijzigingen aangebracht aan de opgestelde tekeningen en worden bijvoorbeeld ook project en sloop P&ID's gemaakt.

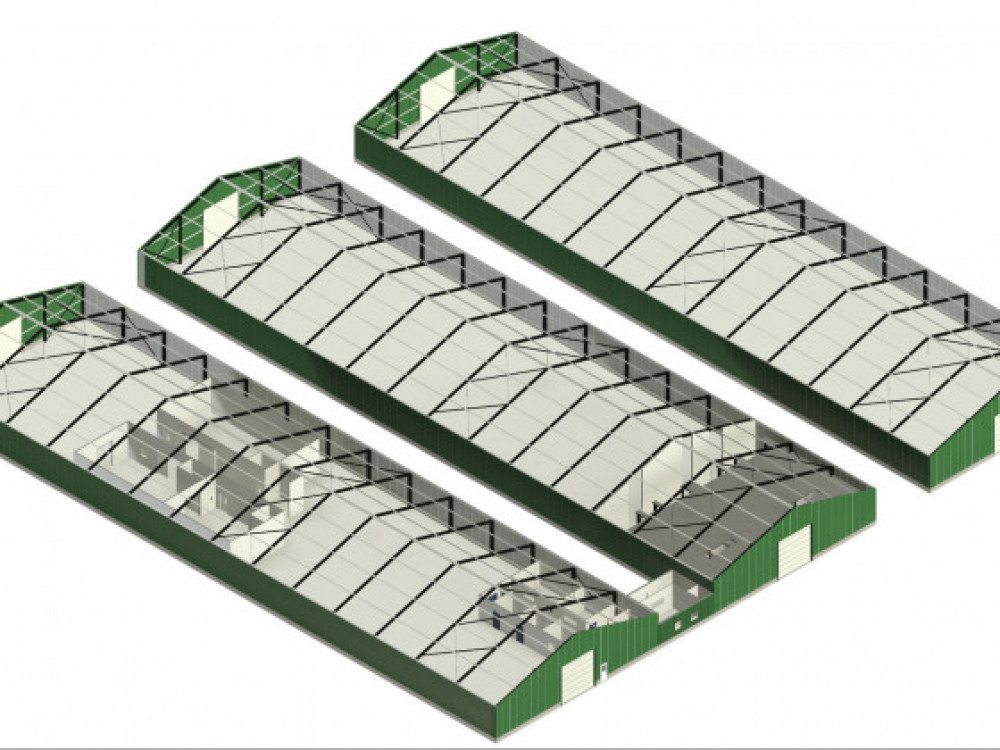

Fruit, Vegetables & Food Ingredients,