Our vision of factories

Dapp was founded in 2009 in the middle of the Betuwe. Since then, we look back on a beautiful and impressive reference list of projects for small, medium and large companies within the Dutch food industry. Customer satisfaction is what drives us, where we work with our clients to realize beautiful projects from design to go-live.

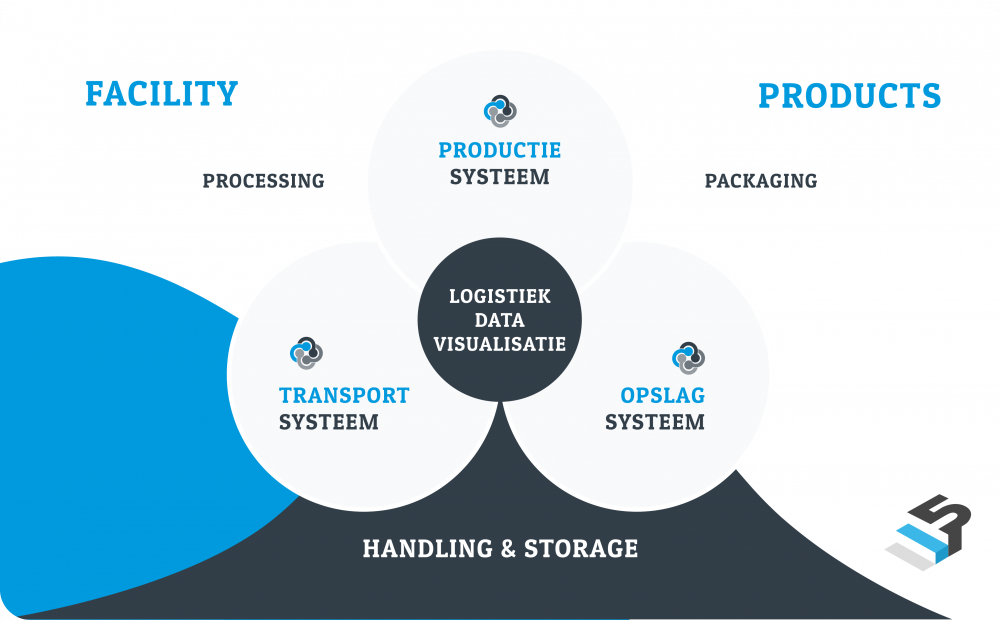

Dapp stands for a team of engineers that combines logistical knowledge with practical experience. We know the workings of factories through and through and can therefore offer practically based solutions using digital and visual means, among other things. As a team, we master integral logistics within factories in combination with mechanization and automation.

We operate on a 'no-nonsense' based business philosophy in which we come up with creative and practical solutions with an open and direct communication style.

Understanding the 'flows' in the factory is our starting point. With an integral view of the total plant and based on facts, we provide insight into the current situation of the plant and identify possible bottlenecks. We believe in a thorough layout study and the translation to improvements in the current factory as well as the future factory layout.

Our integral vision of factories

Of importance is the development of an integral logistics-production vision of the factory based on facts, not gut feelings. Developing this concept first before hooking up architects, contractors and other suppliers is our credo.

We work process-oriented, i.e. products are made in every factory, but every factory is unique in its kind. We understand the processes in order to arrive at targeted solutions and we believe in mapping the processes together with your operational team, then providing them with flow data and any financial data. This coupled with your future requirements not only gives a picture of the current plant and the possible and/or necessary improvements but also gives a picture of the plant in the future.

We present 'what-if' scenarios in order to calculate and visualize not only operational but also strategic decision making that shows the impact on the total plant.