3D scan als verhuis-, archief- en marketingtool bij een verffabriek in Gelderland

Apeldoorn,

April 2025

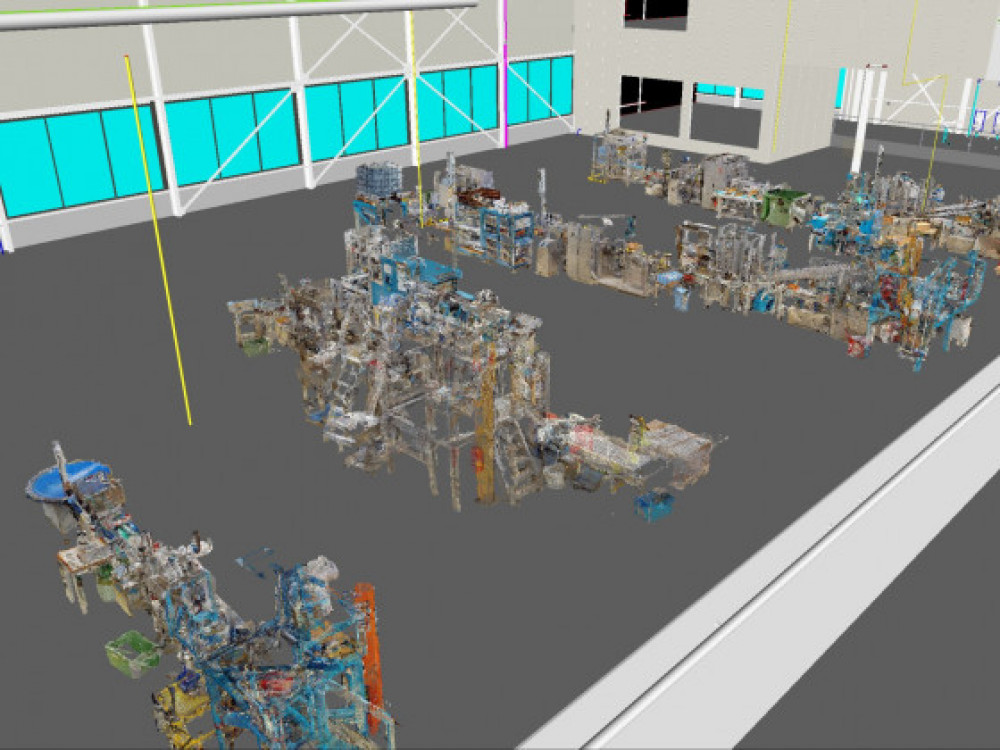

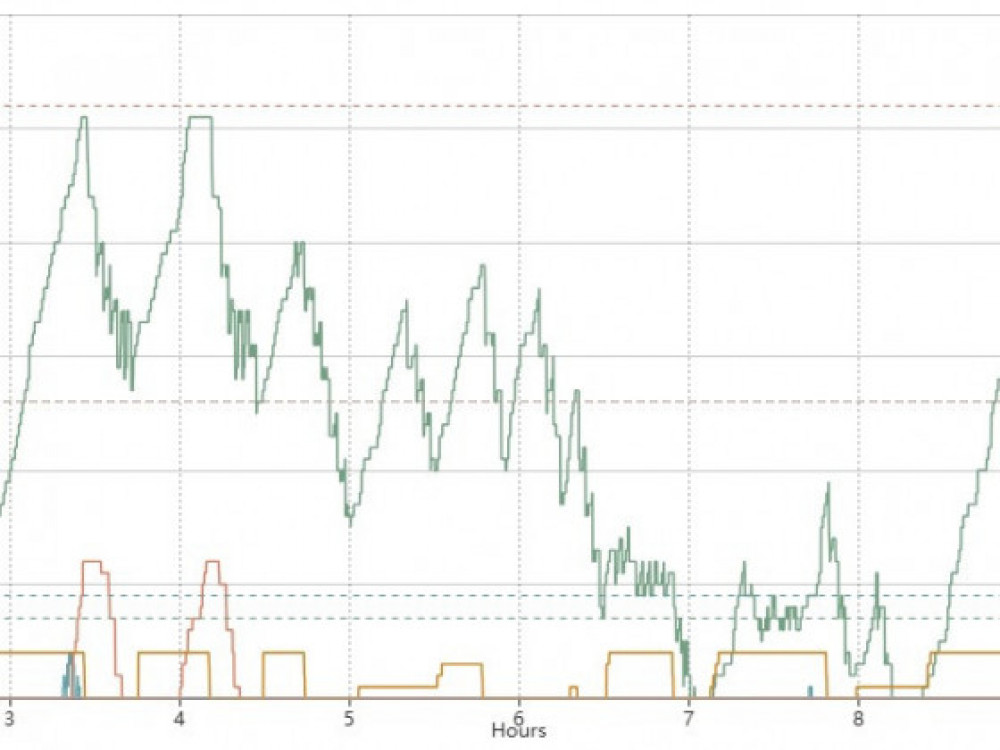

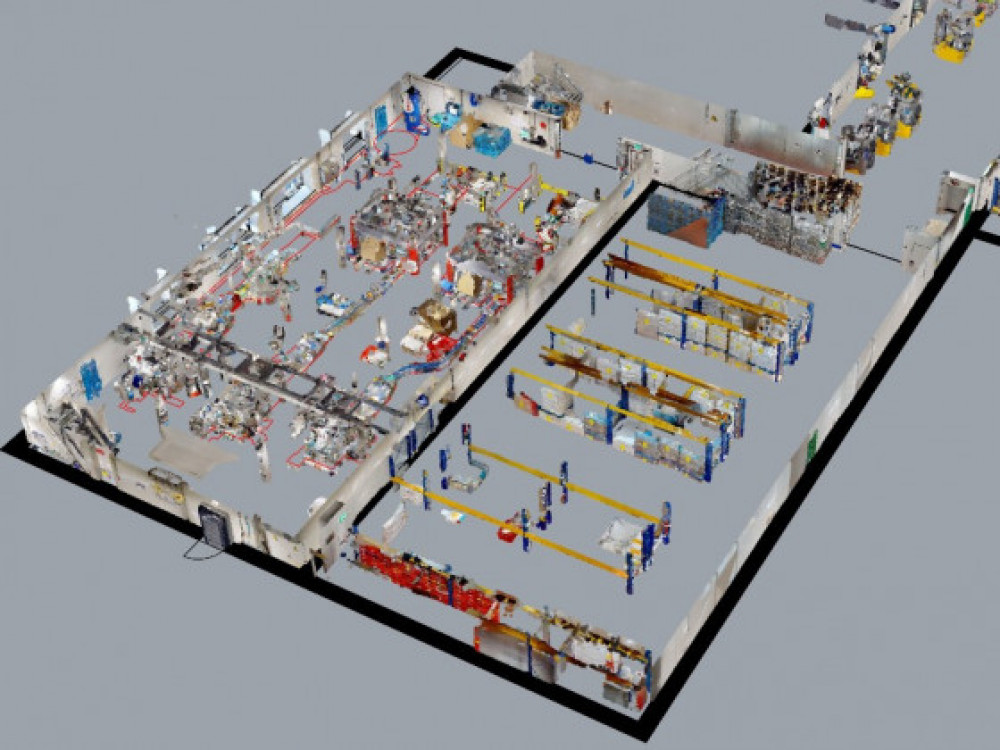

Voor een verffabriek in Gelderland heeft Dapp een uitgebreide 3D-scan uitgevoerd van hun bestaande productielocatie. De klant stond voor een verhuizing naar een nieuwe fabriek en had behoefte aan een nauwkeurig en veelzijdig digitaal vertrekpunt. Met de scan is de volledige oude fabriek vastgelegd - niet alleen als hulpmiddel voor het plannen van de fysieke verhuizing, maar ook als digitaal archief voor toekomstig intern gebruik.

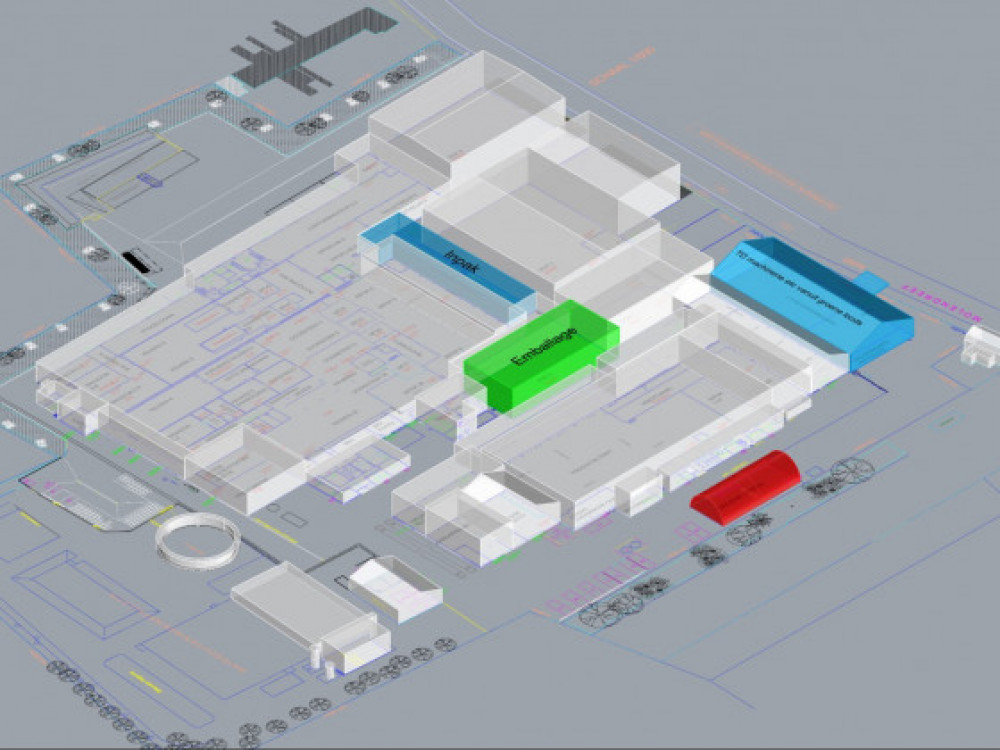

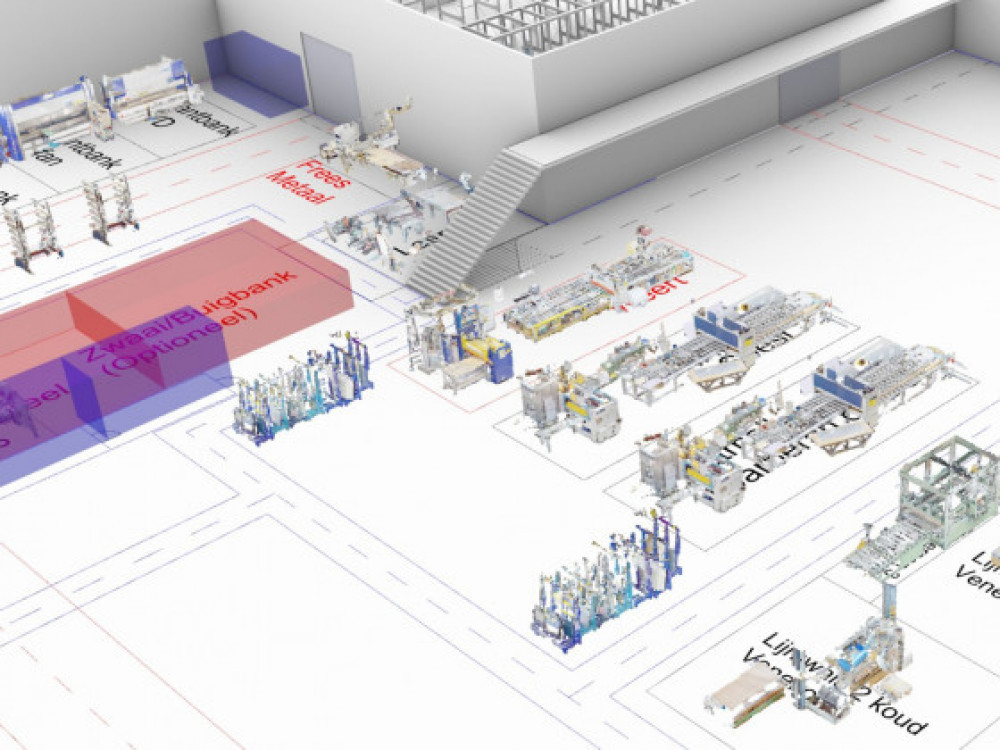

Wat dit project bijzonder maakte, was het brede scala aan toepassingen. De scan werd niet alleen gebruikt om de huidige installaties in kaart te brengen, maar ook om deze machines virtueel te positioneren in de lay-out van de nieuwe fabriek. Dit gaf de klant voor het eerst een ruimtelijk inzicht in hoe de nieuwe opstelling eruit zou zien, wat voorheen alleen mogelijk was met platte 2D-tekeningen. De combinatie van nauwkeurige data en een visuele weergave zorgde ervoor dat layoutkeuzes veel sneller en onderbouwder genomen konden worden.

Daarnaast werd de scan ook commercieel ingezet. In samenwerking met het salesteam van de klant is een online digitale experience tour ontwikkeld, waarmee potentiële klanten, leveranciers of stakeholders de fabriek virtueel kunnen bezoeken. Deze interactieve tour biedt niet alleen een unieke inkijk in het productieproces, maar verlaagt ook de drempel voor kennismaking met het bedrijf - zonder dat daar een fysiek bezoek voor nodig is. Het is de eerste keer dat bij dit soort projecten een 3D-scan ook zo duidelijk een rol speelt in marketing en klantbeleving.

De tour bevat onder andere:

- Klikbare tags bij machines met uitleg of video's van het proces.

- Historische informatiepunten over de ontwikkeling van de fabriek.

- Links naar bijbehorende producten of productpagina's op de website.

- Een automatische rondleiding met begeleidende tekst.

- Mogelijkheid voor externe partijen om zelfstandig de tour te verkennen.

- Inzetbaar op beurzen, websites of in verkoopgesprekken.

Kortom: één scan, vier toepassingen - technisch, logistiek, historisch en commercieel. Een investering met een brede en tastbare meerwaarde.

Non-Food & Logistics,