Mega Industrial Relocation: Perfect Collaboration between Primeale United, Dapp, and Yourtech

When we think of industrial relocations, we typically imagine large machines, extensive paperwork, and maybe even a lot of headaches. The part about large machines is correct. But what if the process from start to finish included smooth logistical efficiency? What if everyone worked together like a well-oiled machine? That's exactly what happened during a recent, complex project where Dapp, Yourtech, and Primeale United joined forces. The result was a revolution in efficiency.

This offers a unique glimpse into a project where an entire machinery park was moved at Primeale United, a food producer specializing in packaged vegetables.

Effective Project Planning in Industrial Relocation

During an online meeting, a powerful team assembled: John Heijboer and Peter van het Woudt from Primeale United. Representing Dapp were Dennis Beijaard and his industrial engineers, Koen van Loon and David den Ouden. From Yourtech, Jan Roel Wolters was present. They discussed the project, which involved merging the Primeale United factory in Ridderkerk with the factory in Dinteloord.

"This isn't a short-term game. The new layout is designed to last for years. That's the essence of strategic efficiency."

The motivation for the project was efficiency. There were two factories performing roughly the same operations. The primary question was whether it would be more practical, efficient, and logical to operate from one location. It wasn't a simple calculation. After an extensive analysis, the conclusion was clear. Merging two factories into one mega-operation in Dinteloord was not only interesting from an efficiency standpoint but also for the future. This is not a short-term game. The new layout is designed to be sustainable for years.

The collaboration between Dapp, Yourtech, and Primeale United led to a remarkably efficient industrial relocation:

- Primeale United as the connecting factor: The role of Primeale United in brainstorming and streamlining communication between different teams.

- Dapp's expertise: Dapp's years of experience in logistical processes and factory layouts streamlined the move.

- Yourtech's innovation: The technical expertise and communication skills brought by Yourtech ensured a smooth transition of production lines.

- Efficient processes: A deep dive into methods that made the complex relocation not only faster but also cost-saving.

- Stunning results: Data and facts that highlight the success of the industrial relocation, including turnaround time, cost savings, and customer satisfaction.

- Teamwork makes the dream work: How joint efforts and synergy were key to the unprecedented success of this project.

Working Together as One Dynamic Team

Initially, the project required secrecy to assess its potential benefits, with measurements and analyses conducted quietly. Only after approval from the board was the team assembled.

"Big challenges call for great teamwork. Not a client-contractor dynamic, but pure, unadulterated collaboration."

John: "Often, you need time to get used to each other. We didn't need an hour for that. There was no client-contractor dynamic. It was a real collaboration where we felt 1: This is really fun to do together. 2: All parties are open to listening to each other. And 3: The plans we had and the plans already made weren't set in stone. All parties were open to jointly make the most of the framework that was already in place. And let's not forget the craftsmanship. Yourtech and Dapp have shown that they can not only make plans but also execute them to perfection."

Secrecy Poses Challenges in Machinery Park Relocations

Yourtech was involved early in the project to assess the needs for relocating the machinery park.

"Under the project name Set-up NL, time was reserved with external parties."

Jan Roel: "Normally, we are involved only after the plans are finalized, but in this case, we were brought in earlier. Postponing the announcement also posed a significant challenge for us. To make the new layout feasible, technical modifications were necessary in Dinteloord. These tasks had to be outsourced. And the time available for these tasks was significantly reduced due to the secrecy. We had to reserve time with various parties without being able to share details initially. Apart from that, everything went as planned."

Support and Acceleration of the Mega Project

Feedback from the shop floor was taken seriously, ensuring broad support and acceleration of the project.

"Input from the shop floor? Crucial. It gave the project wings and support."

Dennis: "The plan was adjusted due to the input from 'those stubborn people from Dinteloord and Ridderkerk'. This was a typical point: We had ideas about it. And you had ideas about it. That was at the stage when people from the shop floor got involved. This led to questions like 'Could it not be done this way or that way because...' 'What would be the effect if we do it this way or that?' The strength lies in listening to each other and seriously considering those ideas. This helped us realize that perhaps it was a better idea. Subsequently, we developed it further."

The Web of Logistics and Teamwork

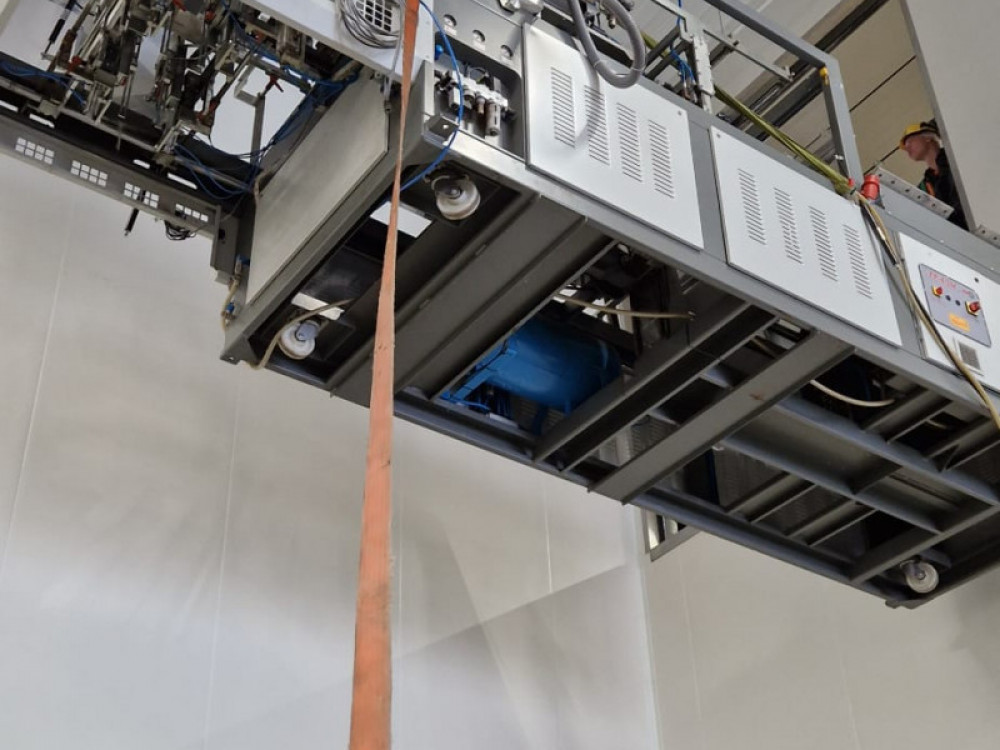

Jan Roel on the relocation: "You are dismantling a factory in Ridderkerk, which is fully operational, and moving it to a factory in Dinteloord, which is also fully operational. And in the Dinteloord factory, lines had to be moved. We kept removing machines and installing them in the new factory.

"In this complex logistical puzzle, one piece was indispensable: safety."

Both the new and old factories were not designed for this. With the dismantling and rebuilding, we had to navigate through everything and ensure it caused minimal disruption to the people. Some spaces were repurposed entirely. This made the industrial relocation logistically extra challenging."

Peter Adds: "Safety was always the priority. We had to implement several measures for this. The operation had to be both food-safe and safe for the people in the vicinity. We encountered situations where things became more dangerous than anticipated. The action was then stopped, discussed, and executed differently."

"It's precision work in terms of time, planning, and the available space. And it's not just about moving the machines, but also about bringing the entire team along. Because everyone was aligned, we managed to complete the project smoothly, well within time, and within budget."

The Perfect Machinery Park Relocation

John: "On time and within budget. An achievement that 99 out of 100 similar complex projects (by other parties) fail to accomplish. Looking back, it sounds easy, but when you start on day one, it's a huge mountain to climb. We professionally dismantled this mountain piece by piece, together. And, importantly, rebuilt it. In hindsight, it seems easy, but it was a tremendously large operation in a very short time, and it went almost flawlessly."

"No overcapacity, no room for errors. Yet, we pulled it off, flawlessly and on schedule."

Dennis: "Three months in an ongoing operation. At a certain point, you no longer have overcapacity. Therefore, delays were not an option. The product planning and everything behind it, like customers, outsourcing, etc., all depended tightly on the schedule. I think almost no one noticed that we were moving machines. Besides, there was a transition of people and their culture. There were two different work methodologies, thoughts, and characteristics."

A Picture is Worth a Thousand Words

Thanks to advanced 2D and 3D imaging, the project could be visually experienced before even a single machine was moved. Dennis continues: "We created a simulation: Will everything fit? Can we process the volume? Does the flow of goods run smoothly and safely? What about the supply of your products to the line?"

"Future scenarios were also taken into account. If you want to expand the line, is there room for that? We considered the attic, where packaging materials are now stored, which are transported to the lines via a lift. In the future, you could think about automating from the attic to the production lines. We brought all these elements together with the help of digital tools."

Innovative Teamwork Strategies Multiplied

"We didn't navigate by intuition, but on an ocean of data."

John: "To describe the collaboration with Dapp and Yourtech urtech, the keywords I'd use are: highly professional, expertise in discussions, and data-backed analysis. All ideas are tested against data. And not just a little data, but shiploads of it. The simulations made from it are then tested again. So, everything is data-driven and not plucked from thin air.

Moreover, the starting point was the foundation to release ideas from different perspectives and expertise. Treating each other as partners, even more as colleagues, made it possible to complete such a task as a team. That was one of the biggest reasons the project was a success. In fact... We've also engaged Dapp and Yourtechfor our project in Africa. That says enough, I think."

"Obstacles? They were immediately smoothed out. No drama, only solutions."

Jan Roel: "It was a busy period, but the collaboration went very well. This made the pressure during the relocation manageable. If there was an issue, it was solved. There were no major problems. This was all due to good preparation and pleasant cooperation."

"Our joint energy took the project to a higher level."

Dennis: "Teamwork was the accelerator. The plans we made and the ideas we expressed received feedback. This made the end result better than what we could have achieved on our own or what Primeale could have done alone. We strengthened each other, optimizing the final result."

"That simulation wasn't necessarily planned."

Koen and David: "As we progressed, we got very well attuned to each other. 'Oh, you can do this and this, can you also do...' This helped us better understand how they wanted certain things. As a result, more came out of the project than we at Dapp had initially envisioned. The simulation, for example, wasn't necessarily planned. It was marked as 'maybe'. The way we eventually merged the lines could be factually substantiated through the simulation model. That was very valuable."

The final word is for Primeale United:

John: "For such a large, or even a smaller project that involves plans like: Internal or external industrial relocations, or new foundation plates for layouts in factories, I would recommend everyone to involve Yourtech and Dapp ."

Peter: "To execute these kinds of large projects properly, you need two parties. Two parties that really want to collaborate and are open to each other. And for that, I couldn't wish for better partners."

9 Reasons to Engage Dapp and Yourtech for Your Industrial Relocation:

- Data-driven decisions: Dapp uses hard and factual data to design the most effective layout.

- Space optimization: Maximum utilization of every square meter for peak productivity.

- Flexible approach: Need layout changes? No problem. Dapp generates your optimal layout.

- Cost-saving: A smart layout means less movement, leading to lower operational costs.

- Future-proof design: Dapp ensures you're ready for the future, whether it's expansion, modification, or technological innovation.

- Complex machines, no problem: Yourtech has a track record of successfully relocating advanced industrial machines and machinery parks. You don't have to worry about expertise; they have it all.

- From A to Z Service: Everything is taken care of, from dismantling machines to transport and installation at the new location, with the option to outsource operational project management. One point of contact, no hassle.

- Safety first: Safety protocols and qualified personnel ensure a risk-free move for both people and machinery. All specialists from both Dapp and Yourtech are VCA certified.

- Time efficiency: The planning is meticulously crafted. No delays, no unexpected costs. That's the promise.

Do you want to relocate your machinery park and/or create a future-proof factory layout? Dapp & Yourtech can handle it. Contact them now!

Contact us