Facility Layout Solution

Facility Layout Solution (FLS) is a tool created by Dapp. This tool optimizes the layout of your plant based on data. Because we only look at this data, and thus take away the gut feeling, we can use Facility Layout Solution to come up with solutions that can save you up to 20% on your material handling costs.

Zoning Plan 2.0

With a so-called zoning plan you can make a global layout of your plant. However, any change in production will probably also bring about changes in the layout. In the food industry, this usually involves many changes. First you expand an existing production line or add a new one. Eventually, so much has changed that the layout has become inefficient and confusing. Processes get mixed up, which means that special solutions have to be invented. Distances are covered that are many times longer than necessary and there is an increasing lack of space. Because this situation is built up over several years, the overview is lost after a while and finding a solution seems an impossible task. It has become so cluttered that you put the problem off and opt for a temporary "solution". Fortunately, it can be done differently!

Discover the most effective layout for your plant

Wouldn't it be great if you could gain insight into how your factory could be laid out efficiently? That you don't just get a global floor plan, but a detailed layout, so you know exactly what goes where? And in addition to that, to gain insight into:

- What can be improved

- Where the efficiency bottlenecks are

- What it would mean to optimize the layout

- How to get from the current situation to the new one

- Where you can best invest in the coming years

- How to make the right choices

- What the impact is of different scenarios

How valuable would it be if you knew about changes in the layout of the factory, so that you can reduce the lead time and with that the material handling costs? In a relatively short time, you are presented with an optimal layout, taking into account all the important processes in the factory, so that you can study where and/or when changes are needed.

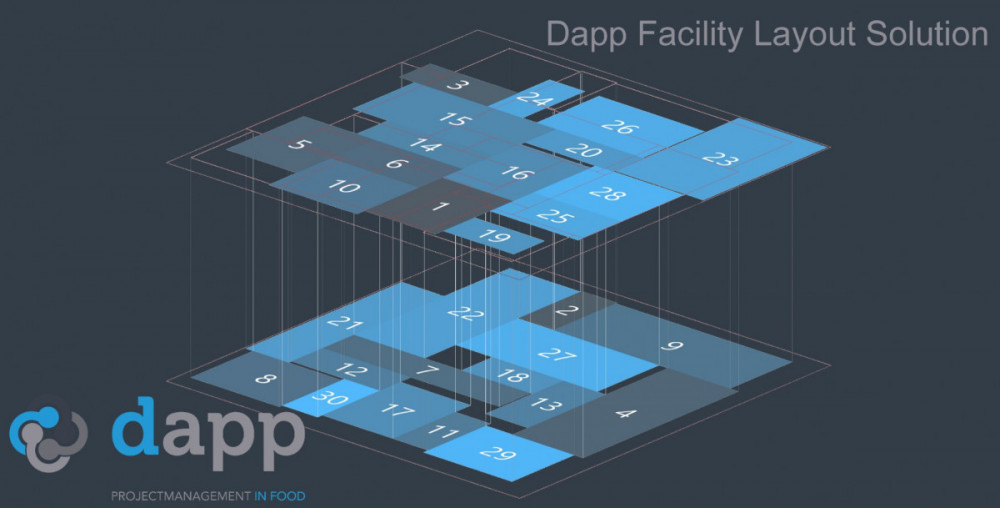

There is a solution, where the plant is viewed integrally. In which the complete plant is mapped. Not just that one piece, no, the entire puzzle. For example, no one can weigh 8 variables against each other in their head. That's 8 to the power 8 to the power 8.... Instead of making decisions based on feelings, FLS allows you to make decisions based on facts and overview. And that in a fast and scientifically substantiated way.

The complex calculations to map out the entire factory are impossible without an advanced computer program. There is (too) much involved and you lose the overview. At Dapp we are comfortable working with 30 variables. And yet it remains clear. As a human being, you can never reason out such an optimal layout. In addition, the production demand can already be different in 2 months. Thanks to Facility Layout Solution these factors are no longer a problem in redesigning your factory.

Curious what Dapp can do for your company in the area of Facility Layout Solution?

Contact us via +31(0)345 50 52 56.

Already interested in how we work with Facility Layout Solution? Above you can download the corresponding product sheet!

Or take a look at the other engineering services we offer. You can find them here.