Our client is an international FMCG player in the food & beverage segment. They work from a large production location in the Netherlands. Production runs continuously, 24 hours a day.

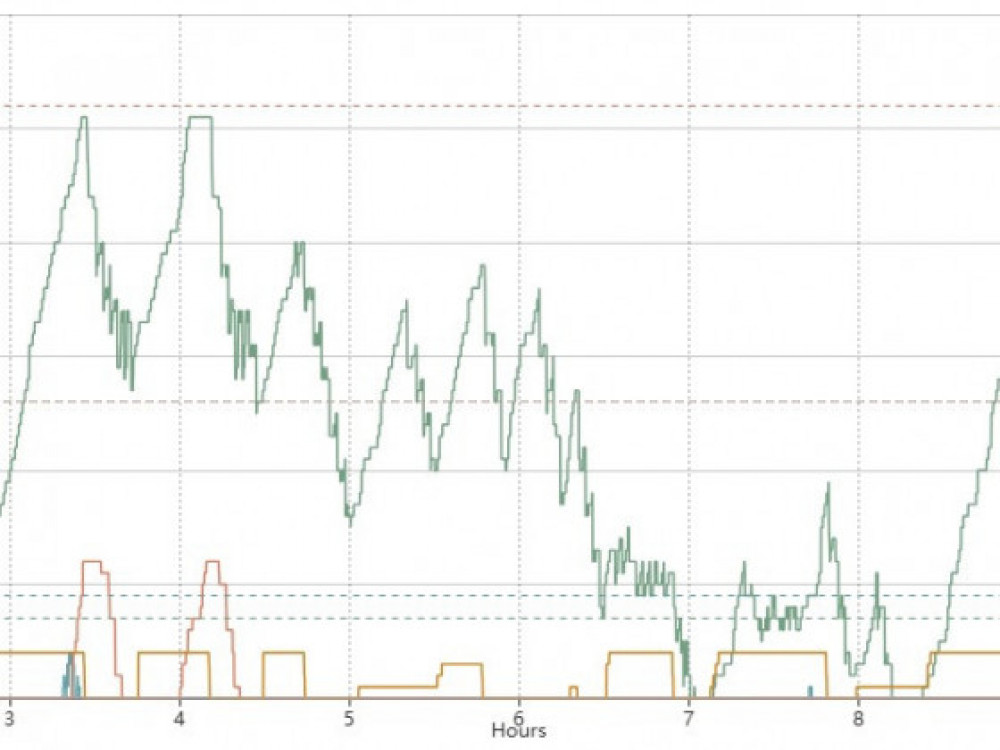

An international audit, in which the various production locations were benchmarked against each other, showed that this production location scored relatively less on the theme of thermal energy consumption. The thermal energy was and is generated on site by means of gas-fired steam boilers. The large loss of energy turned out to be the result of one of the two high-pressure steam pipes that turned out to be incorrectly dimensioned. The line no longer matched current consumption and was too large. This resulted in condensation and thus led to significant energy loss.

DAPP was asked to provide a project manager who could solve this problem. The order that was given concerned a complete design of a new high-pressure steam pipeline. Additional provisions were included in the design to enable this pipeline and the associated production installations to be taken out of operation in a safe manner if necessary. In the old situation this was impossible: during an inspection or during maintenance, the entire production location had to be taken out of operation immediately. A rather drastic and expensive course of action.

Our DAPP project manager was allowed to put together his own team. It was important to him in that choice that a potential team member had a high degree of demonstrable subject matter expertise and experience with the subject. This was important because the assignment turned out to be complex and the resulting risks for the production installation were very high. A controlled and managed transition was a top priority. Any error in the engineering and during realization could lead to a long-term downtime of the entire production location.

In addition to experienced employees from production, engineering and maintenance, our project manager involved various specialized external contractors and suppliers in the project, such as from the inspection body, the 'notified body'.

The DAPP project manager worked together with his team, which at times consisted of as many as 25 members. What he thought was important and wanted to achieve with the project was the improvement of the old existing situation on several levels:

- functional (improved controls, improved measurements);

- safety (applying strength calculations in the design, being able to go into and out of operation in a controlled manner);

- technical (applying innovative techniques, including in the field of insulation);

- costs (by, among other things, choosing the optimal pipeline route).

In order to achieve these objectives, the necessary obstacles had to be removed, sometimes literally. A good example of this is the transit that had to be made through an almost 1 meter thick foundation floor.

Specialists with a lot of experience learned a lot through the application of innovative techniques, also unknown to them. This required good teamwork in which a good constructive atmosphere was important. Everyone took the utmost care to achieve the project success. There was an atmosphere in the project team, when the circumstances demanded it, not to be afraid to deviate from the beaten track in order to arrive at the optimal solution.

During the realization phase, production was stopped twice in order to install the new high-pressure steam pipeline under the necessary time pressure. We managed to keep to the schedule and the new pipeline has now been successfully put into operation. This not only makes an important contribution to energy savings, but also makes it possible to start and shut down production installations in a safe and easy way. The new steam pipeline leads to approximately 2% savings, expressed in MJ/unit of product, on the total thermal energy consumption of the production site. This doesn't seem like much, but in absolute terms it leads to significant savings that pay for the investment in 3 years. All in all, a meaningful, profitable and above all sustainable investment.

The adjustments were also a great opportunity to carry out remediation work on the installation. These are often the final item in the budget and are often forgotten.

This completed the successful delivery and contributes significantly to the full satisfaction of the client and users.